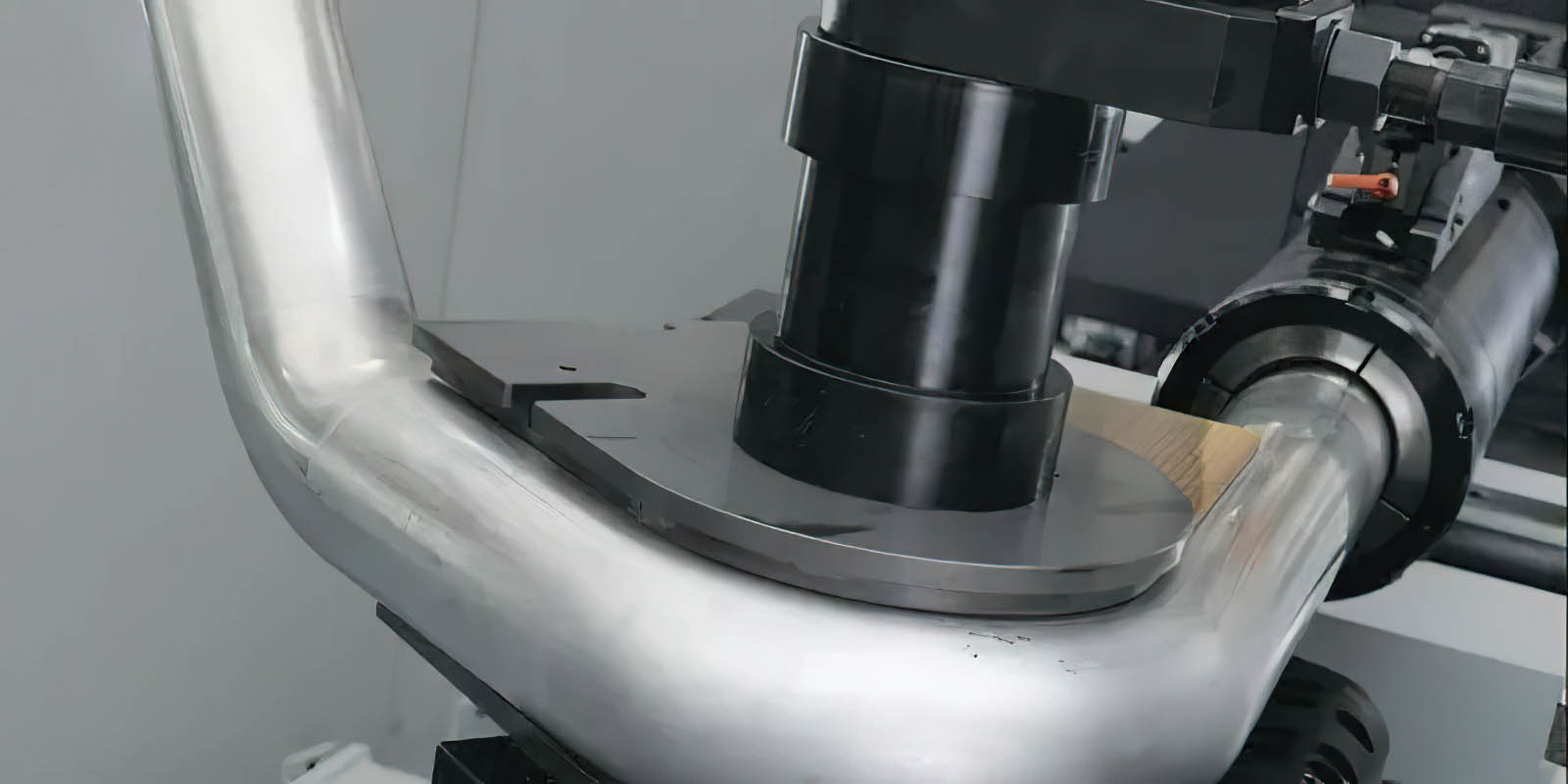

CNC Mandrel Tube Bending

Eliminate Welds and Joints, Lower Fabrication Costs

CNC mandrel tube bending is superior to draw bending for many applications. Mandrel bending allows for tighter radii and less ID deformation. CNC bending of the tubes allows for dimensionally consistent parts that facilitate precision final assemblies. The combination of laser cut and mandrel bent tubes also allows for slot and tab utilization, which in turn reduces jigging, fixturing, and welding of final assemblies.

At Fossil, our CNC tube bender is capable of left or right-handed bends with a capability of tube up to 3.18″/80mm in diameter.

Want to learn more? Call us at 724-204-1515, or visit our Contact page today.

CNC Tube Bending Delivers Precise Bends, Efficient Material Handling, and a Cleaner Finish.

Consistent Bends with No Deformities

At Fossil Industries, our CNC tube bending machines can create complex shapes with high accuracy in a single pass. We are also production oriented, handling large amounts of material at one time to reduce overall production costs.

Serving a vast number of applications, from playground equipment to medical gear.

Maintaining Tube Integrity

One key advantage of computer-controlled tube bending over manual processes is its ability to maintain the overall structural integrity and solidity of tubes and pipes, while achieving the desired bends.

Keeping the material integrity unaffected in tubes and pipes after bending is essential to ensuring the intended use, lifetime, and durability.

Variety of Applications

CNC tube bending delivers exceptional results to a variety of industries, including playground and fitness equipment, medical gear, the automotive industry, and the oil and gas industry.

Fossil Industries handles large scale orders quickly and affordably with consistent and reliable results at a high level of quality.

Want to learn more? Call us at 724-204-1515, or visit our Contact page today. We’re ready to serve your sheet cutting needs and more.